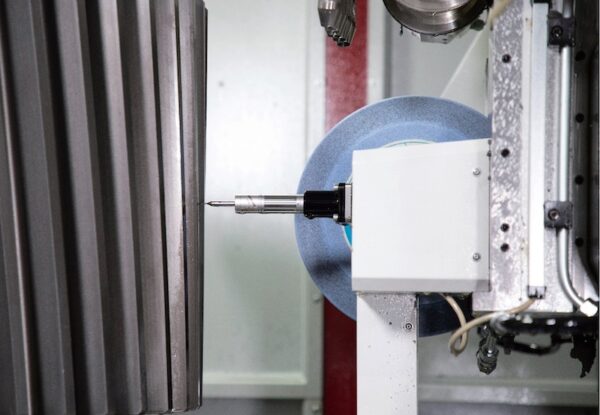

New KAPP NILES ZP16 Boosts Industrial Reducers with German Precision

KAIBO, a leading industrial reducers manufacturer based in China, is thrilled to announce the installation of a KAPP NILES ZP16 High-Precision CNC Gear Grinder in March 2025—strengthening our commitment to custom gearbox manufacturing for mining, marine, oil & gas, rubber/plastic , and heavy machinery industries. This state-of-the-art machine joins our existing fleet of advanced equipment, including KAPP NILES ZE400, ZE800,ZE1200, ZP20, and Gleason high-speed hobbing machines, creating a robust ecosystem for precision reducer production.

Key Technical Innovations from the KAPP NILES ZP16

-

Ultra-Precision Grinding (≤1μm Positional Accuracy)

- Delivers aerospace-grade precision for internal/external gears, ideal for high-torque planetary gearboxes (e.g., P06, KAF57 models) and rotor components meeting IP65 protection standards.

- Dual-column design minimizes vibration, ensuring a surface finish quality that reduces friction and noise in robotic and automotive systems.

-

Versatility for Diverse Applications

- Processes gears up to 3,000mm in diameter and 40mm module, catering to both compact robotic reducers and large mining/conveyor gears.

- Supports form grinding, profile grinding, and topological modifications in a single setup, cutting tooling costs by 30% and downtime by 40% for custom solutions.

-

Smart Factory Integration

- Equipped with the Siemens Sinumerik 840D CNC system for real-time IoT-enabled process optimization, enabling predictive maintenance and remote monitoring via AI-driven analytics.

- Works seamlessly with Jiangsu Topus’ force-control clamping technology to ensure 99.9% workpiece safety during high-load operations.

Industry-Specific Advantages for Global Clients

- Petrochemical Industry: High-temperature and corrosion-resistant reducers, engineered to withstand harsh chemical environments. Our products meet API standards and undergo rigorous material testing, ensuring reliable performance in refineries, chemical plants, and offshore platforms.

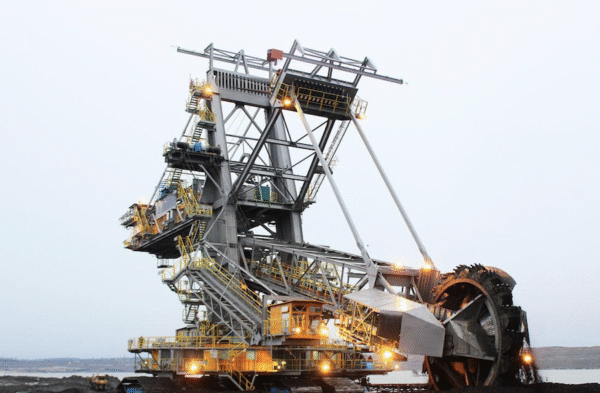

- Mining & Heavy Machinery: Heavy-duty reducers with large-module gears built for extreme load conditions. Tested to endure rugged terrains and continuous operation, our solutions power excavators, haul trucks, and conveyor systems, reducing downtime and maintenance costs in mining operations.

- Marine & offshore engineering Industry: Marine-grade reducers compliant with ABS, DNV GL, and Lloyd’s Register standards. Engineered for high torque and low vibration, they drive propulsion systems, deck machinery, and cargo handling equipment, ensuring smooth operation and safety at sea.

Sustainability Meets Efficiency

- 20% Lower Energy Consumption: Optimized motor systems reduce electricity use compared to conventional grinders, aligning with global ESG goals.

- 15% Less Material Waste: Advanced grinding algorithms minimize raw material removal, lowering costs and environmental impact—critical for sustainable manufacturing.

Why KAIBO’s Expanded Capabilities Matter

- Rapid Turnaround: 21-day prototyping for custom gears and 40% faster setup times, ideal for urgent OEM and replacement part orders.

- Certified Quality: All reducers undergo 100% load testing in our dedicated industrial reducer QC center, backed by ISO/CE/UL/RoHS certifications for global compliance.

- Global Support: 24/7 technical service via KAPP NILES’ Changzhou team, ensuring seamless collaboration for overseas clients in 10+ countries.