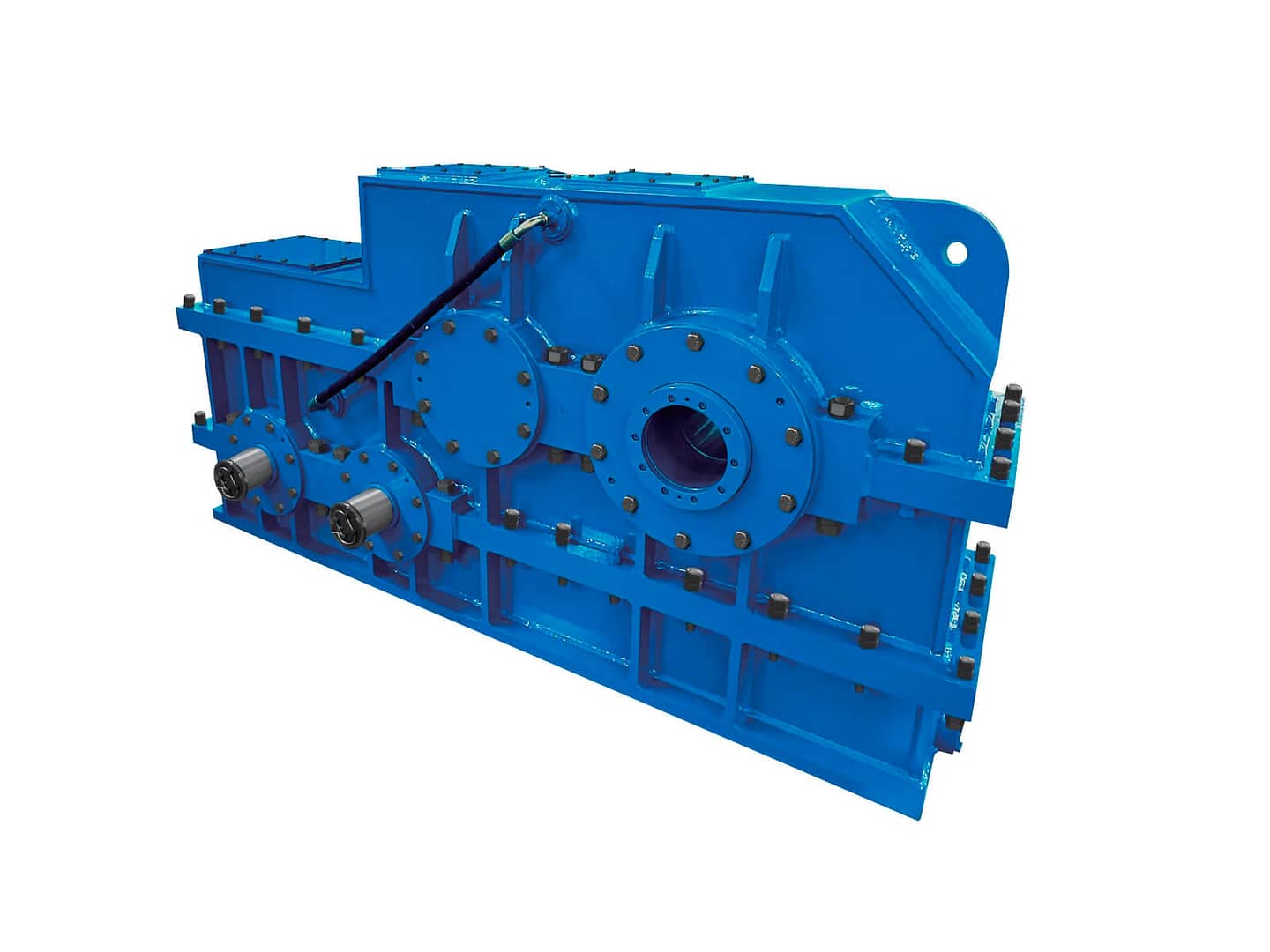

Oil Drilling Gearbox

KAIBO’s oil drilling gearbox, engineered for harsh environments, delivers torque, low vibration, long life via precision gears, rugged housing & advanced cooling. Ideal for onshore/offshore rigs, deep-well & mud pump apps, it ensures 97% efficiency in high temps. As custom gearbox manufacturer, we tailor solutions for corrosion-resistant offshore drives, with fast customization & 24/7 support.

Product Overview

KAIBO's Oil Drilling Gearbox, API-certified and custom-engineered for oil & gas drilling applications (onshore rigs, offshore platforms, deep-well systems), solves high-load power transmission challenges in extreme environments. Constructed with 42CrMo4 precision gear grinding and heat-treated alloy steel housing, it ensures 97% efficient operation with ≤80dB noise levels, reducing energy consumption by 12% for top drive systems and enabling stable performance in 150°C high-temperature wells. As a custom industrial gearbox manufacturer, we tailor solutions to unique drilling requirements.

Core Advantages

- High-strength alloy steel housing: Resists corrosion, impact, and thermal expansion in harsh drilling conditions.

- Precision-cut spiral bevel gears: Heat-treated for smooth torque transmission and minimal wear.

- Integrated forced-cooling system: Maintains optimal oil temperature (≤75°C) during continuous heavy-duty operation.

- Custom drilling design: Supports high-torque loads for top drives, mud pumps, and rotary tables as a leading custom industrial gearbox manufacturer.

- Low vibration & noise: ≤80dB (loaded) via vibration-dampening mounts and gear optimization.

- Rigorous API testing: Ensures reliability in offshore saltwater, high-pressure, and extreme temperature environments.

- Low maintenance design: Reduces downtime with minimal upkeep

- Durable construction: Engineered for long service life in harsh conditions

Application Scenarios

- Onshore oil drilling rigs with top drive systems

- Offshore platforms requiring corrosion-resistant gearboxes

- Deep-well drilling (≥5,000m) with high-torque rotary drives

- Mobile drilling rigs for remote site operations

- Mud pump systems in horizontal directional drilling

Technical Specifications

| Parameter | Typical Value | Notes |

|---|---|---|

| Input Power | 100–1,000 kW (Customizable) | Suits top drives and mud pumps, with manufacturer-tailored power ratings. |

| Input Speed | ≤1,500 RPM | Matches standard motors, fine-tuned by our manufacturing engineers. |

| Gear Ratio | 3–30 (Customizable) | High torque for deep drilling, customized per manufacturer’s expertise. |

| Output Torque | 20,000–150,000 N·m (Customizable) | Drives large drill pipes, designed for heavy loads by a leading manufacturer. |

| Output Speed | 50–500 RPM (Ratio-dependent) | Adjusts for drilling speed, with manufacturer-supported ratio optimization. |

| Mounting Method | Flange (standard); Custom shaft | Quick installation, with custom mounting from our manufacturing team. |

| Protection Grade | IP67 (IP68 Optional) | Dust/water protection, ideal for offshore use—manufacturer-certified. |

| Noise Level | ≤80 dB (Loaded, 1m Distance) | Meets industrial standards, ensured by our manufacturing quality control. |

| Efficiency | ≥96% (Depends on Ratio) | High efficiency reduces fuel costs, a manufacturer-backed advantage. |

3-Step Quick Selection

- Identify Drilling Application: Specify onshore/offshore/deep-well needs—our manufacturing team understands unique loads.

- Share Core Parameters: Input speed, gear ratio, torque—get manufacturer-recommended models in 24h.

- Request Custom Solutions: Explosion-proof/high-temperature designs, with 6–8 week lead times from our factory.

Ready to Revitalize Your Oil Drilling Process? Let's Talk

FAQs

Q: How much does an oil drilling gearbox cost?

A: Prices vary based on input power, torque requirements, and customization. As a custom gearbox manufacturer, we provide tailored quotes within 24 hours—contact info@kaiboi.com for a detailed estimate.

Q: Can the gearbox be used in explosion-proof environments?

A: Yes—we offer explosion-proof (ATEX/IECEx certified) gearboxes for hazardous zones. Custom designs integrate flameproof housings and spark-resistant components for offshore and onshore explosive environments.

Q: How does your manufacturing team recommend maintaining gearboxes?

A: Replace oil every 1,000–1,500h (new units), then quarterly with ISO VG 460 EP. Our manufacturers advise monthly gear/bearing inspections and temperature/vibration monitoring.