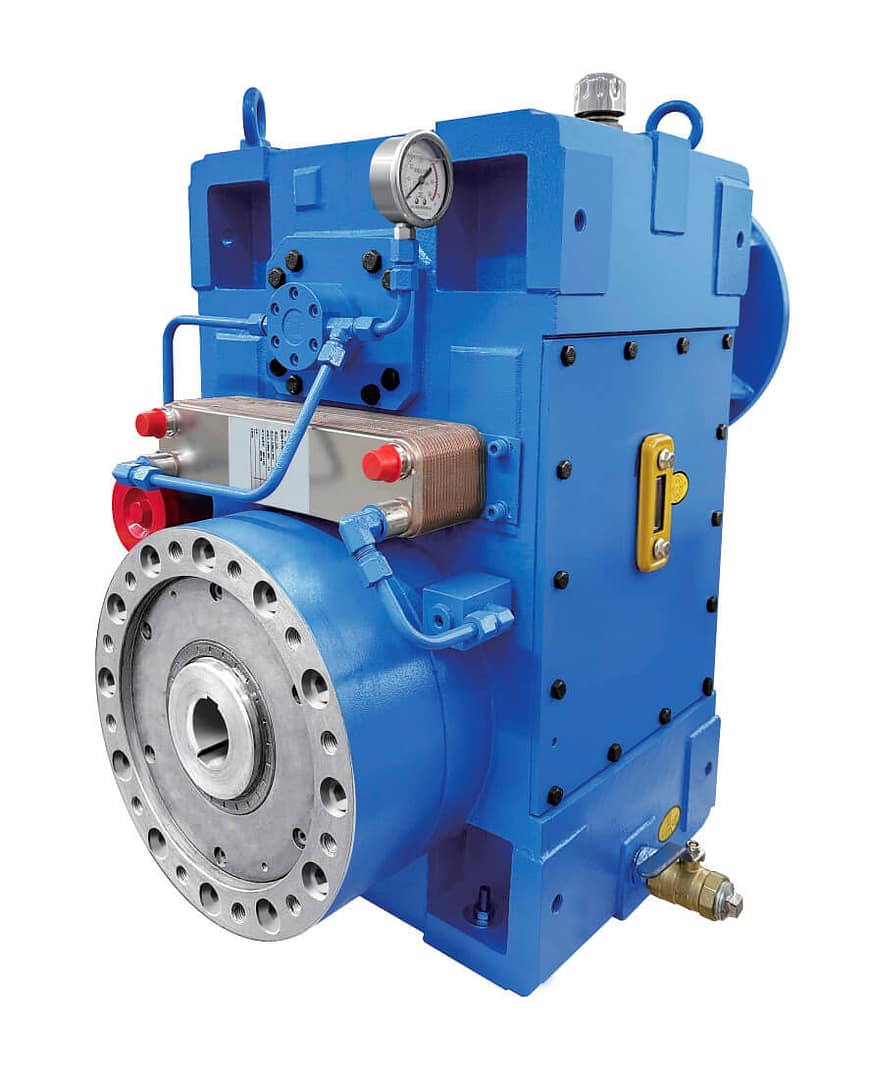

High-Torque Extruder Gearbox

KAIBO’s high-torque extruder gearbox is engineered for plastic extruders. With precision-ground gears, a robust housing, and advanced lubrication, it offers high torque transmission, low noise, and long-term reliability. Ideal for granulators, cast film lines, and sheet extrusion machines. Fast delivery and excellent after-sales support.

Product Overview

KAIBO's High-Torque Extruder Gearbox, ISO 9001-certified and custom-engineered for plastic extruders (granulators, cast film, sheet lines), solves high-load power transmission challenges with 18CrNiMo7-6 precision gear-grinding and ductile iron housing—delivering low-noise, 98% efficient operation that cuts energy costs by 15% for PP/PE granulation and 200m/min high-speed film production.

Core Advantages

- High-strength alloy/ductile iron housing resists deformation/corrosion.

- High-grade alloy gears: heat-treated, precision-ground for smooth transmission.

- Advanced forced-lubrication reduces friction, boosts efficiency.

- Custom-extruder design handles high loads, stabilizes large screws.

- Optimized gears + precision machining: noise ≤75dB (no-load).

- Rigorous testing ensures long service life, low maintenance.

Application Scenarios

- High-speed screw drives for PP/PE granulation

- High-speed cast film lines (thickness control)

- Heavy-load sheet extrusion (ABS/PVC sheets)

- Energy-efficient continuous production systems

- High-precision film/sheet quality assurance

Technical Specifications

| Parameter | Typical Value | Notes |

|---|---|---|

| Input Power | 0.75–75 kW(Customizable) | Suits granulators, cast film, and sheet extrusion. |

| Input Speed | ≤3000 RPM | Matches standard extruder motors; stable screw drive. |

| Gear Ratio | 5–50(Customizable) | High torque for low/high-speed: granulation/cast film. |

| Output Torque | 8,000–50,000 N·m(Customizable) | Stable drive for large-diameter screws in heavy loads. |

| Output Speed | 50–1500 RPM, Ratio-dependent | Adjusts via gear ratio for 30–200m/min production. |

| Mounting Method | Flange (standard); Shaft (custom) | Quick assembly or retrofitting for non-standard setups. |

| Protection Grade | IP54(IP65 Optional) | Dust/moisture protection; IP65 for extreme environments. |

| Noise Level | ≤75 dB(No-load, 1m Distance) | Low noise for quiet operation in production lines. |

| Efficiency | ≥95%(Depends on Ratio) | High efficiency reduces energy costs for continuous runs. |

3-Step Quick Selection

- Identify Equipment Type

Determine if it’s for granulation, cast film, or sheet extrusion—each has unique load requirements. - Share Core Parameters

Provide input speed, desired transmission ratio, and output torque. Our technical team will recommend suitable models within 24 hours. - Request Custom Solutions

For special needs (high-temperature, explosion-proof, non-standard interfaces), we offer tailor-made designs with 4–6 week lead times.

Ready to Revitalize Your Extrusion Process? Let's Talk

🌎 Visit Our Website: https://kaiboi.com

📧 Request A Quote: info@kaiboi.com

📂 Free Download : Extruder Gearbox Selection Manual.PDF

FAQs

A: Start by sharing your equipment type and operating parameters (speed/torque). Our engineers will analyze compatibility and propose options—no calculator needed, just direct technical consultation.

A: Standard models ship within 72 hours. Custom designs take 4–6 weeks, with real-time order tracking provided.