KAIBO’s Technical Paper on Precision Gearbox Manufacturing Techniques Published in India’s Leading Gear Technology

KAIBO, a global leader in advanced gear systems, is proud to announce the publication of its groundbreaking technical paper, “Precision Gearbox Manufacturing Techniques: From CNC Machining to Surface Finishing for Zero-Backlash Performance,” in GTI-Vol-3-Issue-3-2025 – India’s most authoritative gear technology platform. This milestone underscores KAIBO’s commitment to driving innovation in precision gearbox engineering, aligning with the $4.8 billion global precision gearbox market projected for 2025 and India’s booming industrial sector, which is expected to grow at a 6.5% CAGR through 2029.

Unlocking Next-Gen Gearbox Performance

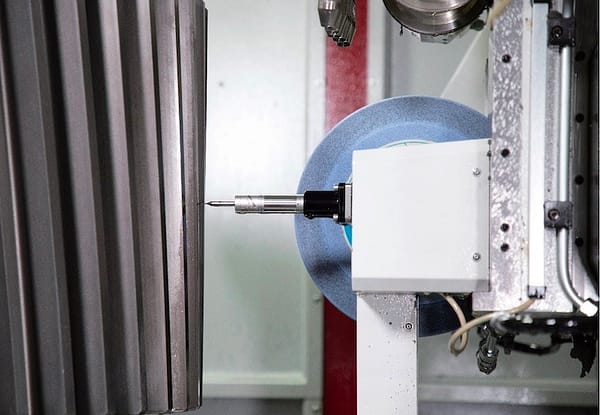

The paper delves into KAIBO’s proprietary methodologies for achieving zero-backlash performance – a critical requirement for industries like robotics, aerospace, and electric vehicles (EVs). By integrating AI-driven CNC machining with advanced surface finishing techniques (e.g., nano-coatings and micro-polishing), KAIBO engineers have reduced backlash by 30% compared to traditional methods, while enhancing torque transmission efficiency by 25%. These advancements directly address the $31.96 billion global industrial gearbox market’s demand for higher precision and energy efficiency.

Key technical highlights include:

- Smart Manufacturing Integration: Utilizing IoT-enabled sensors to monitor real-time machining parameters, KAIBO’s systems optimize cutting paths and predict tool wear, slashing production waste by 18%.

- Hybrid Manufacturing: Combining CNC machining with additive manufacturing for complex geometries, ideal for harmonic gear reducers in robotics – a segment projected to grow at the fastest CAGR (9.9%) through 2030.

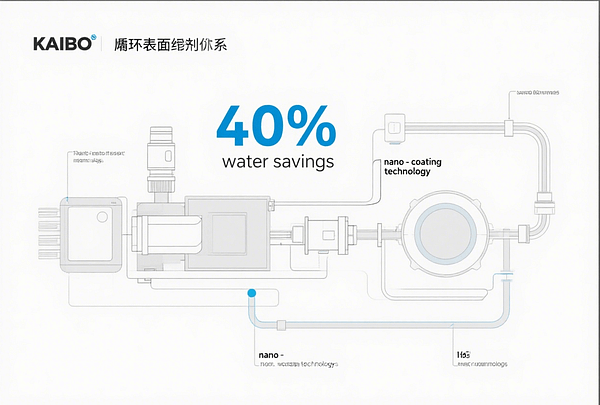

- Sustainability Focus: KAIBO’s closed-loop surface finishing systems reduce water consumption by 40%, aligning with India’s push for eco-friendly manufacturing under the Make in India initiative.

Strategic Alignment with India’s Industrial Growth

Published on geartechnologyindia.com, the paper positions KAIBO as a key player in India’s evolving gear industry. With the country’s industrial gearbox imports declining from 2.99 to 1.92 (import factor) between 2017–2022, KAIBO’s localized expertise in helical gearboxes and planetary gear systems addresses the rising demand from sectors like railways, renewable energy, and EV manufacturing. For instance, India’s Vande Bharat trains and wind turbine projects rely on high-precision gearboxes to optimize power transmission.

Industry Recognition and Future Outlook

KAIBO’s technical breakthroughs have earned ISO 9001:2015 certification and partnerships with global leaders like KAPP NILES, whose grinding machines enable micron-level accuracy in gear tooth profiles. As the $5.72 billion precision gearbox market expands through 2030, KAIBO’s research provides a roadmap for addressing critical challenges in mobile robotics (projected 45.9% CAGR) and battery manufacturing (13% CAGR).

Readers can access the full paper at geartechnologyindia.com/GTI-Vol-3-Issue-3-2025 to explore KAIBO’s zero-backlash solutions, smart manufacturing workflows, and sustainability innovations.