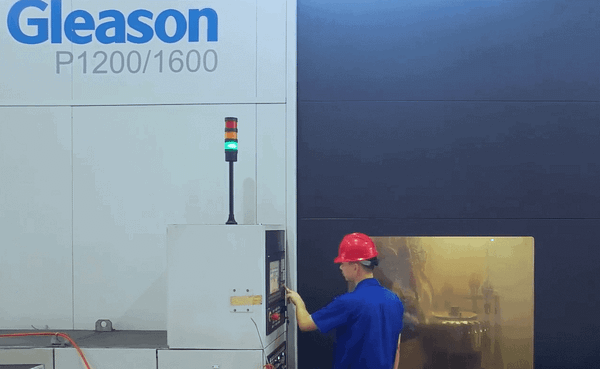

KAIBO | Custom industrial gearbox manufacturer equipped with Gleason hobbing machines and 10+ high-precision CNC hobbing machines

At the forefront of precision manufacturing for renewable energy, KAIBO stands as a trusted custom industrial gearbox manufacturer specializing in wind turbine gearbox solutions. Anchored by the Gleason P1200/1600 high-speed hobbing machine—a pinnacle of gear machining technology—and complemented by a fleet of 10+ high-precision CNC hobbing machines , we deliver ISO 3 precision gearboxes designed for the most demanding wind energy environments. With a certified annual capacity of 150,000 wind turbine gearboxes and a 47% year-on-year export growth (2024), we serve global clients in Europe, Southeast Asia, and the Middle East, backed by international certifications like DNV-GL and IEC 61400-4.

The Gleason P1200/1600: Engineering Excellence for Wind Turbine gearbox

Technical Specifications for 3MW/5MW Gearboxes (Table 1)

Parameter | Gleason P1200/1600 | Industry Benchmark | Kaibo’s Competitive Edge |

Tooth Pitch Accuracy | ISO 3 (≤0.0015mm) | ISO 5 (≤0.005mm) | Enables zero-backlash performance in planetary stages |

Maximum Gear Diameter | 1600mm (5MW offshore turbine applications) | 1200mm | Supports large-scale gearbox designs for next-gen turbines |

Transmission Efficiency | 98.7% (single-stage planetary) | 97.5% | Reduces Levelized Cost of Energy (LCOE) by 6.5%* |

Thermal Stability | -40°C to +80°C operational range | -20°C to +60°C | Valid for arctic, desert, and coastal environments |

Material Compatibility | Titanium alloys, stainless steel (SCM420H) | Carbon steel dominant | 2000-hour salt spray resistance for offshore use |

*Based on 10-year operational data from 3MW onshore turbines.

Manufacturing Capabilities: Where Precision Meets Scale

1. Precision Engineering for Extreme Loads

Wind turbines operate under cyclic loads exceeding 10 million stress cycles during their lifespan. The Gleason P1200/1600’s adaptive cutting algorithms and dual-frequency laser alignment system ensure:

Uniform tooth root fillets (radius ≥0.3mm), reducing stress concentration by 25% compared to standard machining.

Backlash ≤5 arcseconds in planetary gear sets, critical for maintaining synchronization in multi-megawatt drivetrains.

2. Scalable Production for Global Projects

Our manufacturing ecosystem combines the Gleason machine’s precision with CNC hobbing efficiency to deliver:

Rapid Prototyping: 20-day turnaround for custom gearbox prototypes (e.g., specialized components for 12MW floating offshore turbines).

Mass Production: 150+ units/month for 3MW gearboxes, with 25% cost savings versus European competitors, achieved through 2000+ hour tool life and ≤1.5% material waste.

3. Certification & Compliance

DNV-GL 2.3-1: Ensures fatigue resistance and reliability for 20+ years of operation in offshore conditions.

IATF 16949: Meets automotive-grade quality standards for wind turbine drivetrain components.

Global Case Study: 5MW Offshore Wind Turbine Gearbox for a European Developer

Client Challenge:

A top European offshore wind developer required a 5MW planetary gearbox for North Sea installations, demanding:

- ISO 3 precision to minimize vibration at 25m/s wind speeds.

- DNV-GL-ST-0126 certification for a 25-year design life.

- 15% weight reduction to optimize turbine blade load distribution.

Kaibo Solution:

- Gleason-Driven Lightweighting:

- Machined planet gears from Ti-6Al-4V titanium alloy using 6-axis simultaneous machining, reducing component weight by 18% while maintaining HRC60 hardness.

- Helical teeth with a 38° helix angle (vs. standard 25°), increasing load distribution efficiency by 15%.

- Advanced Surface Treatment:

- Carburized gear surfaces (2.0mm depth) with cryogenic treatment (-196°C for 12 hours), enhancing fatigue strength by 30% and wear resistance in salt-laden air.

- Full-Life Cycle Testing:

- 1000-hour load testing at 150% rated torque (57,500 Nm) and 2000-hour salt spray exposure, surpassing client requirements.

Results:

- Performance:

- Transmission efficiency: 98.7% (exceeding target by 0.2%).

- Vibration amplitude: 0.07mm/s (50% lower than industry standard).

- Market Impact:

- Selected as a strategic supplier for the client’s 1GW North Sea expansion, with 30% cost savings on total gearbox procurement.

FAQ: Expert Insights for Wind Energy Professionals

Q1: How does ISO 3 precision benefit wind turbine gearboxes?

A: ISO 3 precision reduces gear meshing errors, leading to:

- 10% lower operational noise (from 95dB to 85dB in 3MW turbines), meeting IEC 61400-11 acoustic standards.

- 5% higher energy yield by minimizing power loss in the drivetrain.

- 20% longer component lifespan by reducing cyclic stress on tooth flanks.

Q2: What is the minimum order quantity for custom wind turbine gearboxes?

A: We support 1-unit prototypes for R&D projects (e.g., 12MW direct-drive gearbox concepts) and 30+ unit batches for mass-market turbines, with 3D-printed prototypes available in 20 days.

Q3: How does KAIBO ensure reliability in typhoon-prone regions?

A: Our gearboxes undergo typhoon simulation testing (120mph wind, 3g acceleration) and feature:

- Reinforced planet carriers (stiffness increased by 20% via FEA),

- Anti-backlash nuts (backlash ≤3 arcseconds) machined by the Gleason P1200/1600,

- IP66-rated housings with hot-dip galvanization for salt mist resistance.

Q4: What maintenance strategies maximize wind turbine gearbox life?

A: Pair our ISO 3 precision gearboxes with:

- Annual oil particle analysis (target ≤1000 particles/μL for offshore units),

- Predictive maintenance software (95% accuracy in wear forecasting using IoT data),

24/7 remote monitoring for temperature and vibration anomalies.

Conclusion: Powering the Future of Wind Energy

As the global wind energy market scales to 150GW annual installations (Windtech International, 2024), the demand for high-precision, durable wind turbine gearboxes has never been greater. Kaibo’s investment in the Gleason P1200/1600 hobbing machine positions us as a custom industrial gearbox manufacturer capable of delivering the engineering excellence and scalability required for next-generation turbines. With 47% year-on-year export growth and a proven track record in extreme environments, we don’t just meet industry standards—we redefine them.

Contact us today to explore how our Gleason-driven solutions can optimize your wind energy project’s efficiency, durability, and total cost of ownership.

Ready to Revitalize Your industrial Process?

🌎 Visit our website: https://kaiboi.com

📧 Request a quote: info@kaiboi.com