5 pasos esenciales para dominar el mantenimiento y la selección de reductores de minería para una vida útil más larga 40% y un ahorro $50K

Las operaciones mineras dependen en gran medida de las cajas de engranajes para accionar equipos críticos, pero estos caballos de batalla a menudo son víctimas de fallos prematuros, paradas imprevistas y costes de mantenimiento excesivos. Según un Encuesta mundial sobre el mantenimiento de cajas de cambios 2024 según GlobalData, los costes de mantenimiento y reparación surgieron como la segunda mayor presión de costes para los operadores mineros en 2023, con 65% de los encuestados citando el aumento de los gastos. ¿Cuáles son las causas? Mala selección de condiciones operativas y reactivas, tal y como se destaca en las mejores prácticas de la norma ISO 10825. Esta guía esboza un marco de 5 pasos de eficacia probada, desarrollado por KAIBO, una empresa líder en el sector del mantenimiento a medida. caja de engranajes para minería para optimizar la selección y el mantenimiento de las cajas de cambios. Alineada con las normas AGMA 9005-A01, esta metodología ha proporcionado un aumento de la vida útil de 40% y un ahorro anual de más de $50.000 en costes para flotas mineras de todo el mundo.

Paso 1: Realizar un diagnóstico exhaustivo de las condiciones de funcionamiento

Análisis del perfil de carga

- Cálculo del par dinámico: Multiplique el par máximo por un factor de seguridad de 1,5 (por ejemplo, un par máximo de 2.000 N-m requiere una caja de cambios nominal de 3.000 N-m) para hacer frente a los choques repentinos.

- Coincidencia del tipo de accionamiento: Elija reductores planetarios para aplicaciones de alto par (cargadoras subterráneas) y unidades de ejes paralelos para necesidades de alta eficiencia (cintas transportadoras).

Perfiles medioambientales

- Resistencia al polvo y la humedad: Especifique IP67 para minas a cielo abierto (protección contra el polvo y la arena) e IP68 para emplazamientos subterráneos (anticondensación).

- Temperatura: Utilice lubricantes sintéticos para temperaturas extremas (-40°C a 60°C) y disipadores de calor mejorados para entornos tropicales.

Configuración de la línea de base de mantenimiento

| Inspección | Frecuencia | Método | Umbral de alarma |

|---|---|---|---|

| Contaminación por petróleo | 200 horas | ISO 4406 Recuento de partículas | >20/18/15 Código |

| Temperatura del rodamiento | En tiempo real | Termografía infrarroja | ΔT >15°C frente al valor basal |

Paso 2: Aplicar 6 criterios básicos de selección

Métricas técnicas

- Densidad de par: Una mayor densidad de par 30% (por ejemplo, diseños compactos para minería de vetas estrechas) minimiza el espacio sin comprometer la potencia.

- Eficacia: Las cajas de cambios de transmisión directa con un rendimiento del 98,5% ahorran 120.000 kWh/añoequivalente a $8.400 en costes de electricidad para una mina mediana.

- Resistencia a la fatiga: Los revestimientos como el DLC (carbono tipo diamante) aumentan la resistencia a las picaduras en 50%, superando más de 1.000 horas de pruebas de niebla salina.

Coste total de propiedad (TCO)

CTP = Coste de adquisición + Gastos de mantenimiento (aceite, filtros, mano de obra) - (Ahorro de tiempo de inactividad + Ahorro de energía)

Dé prioridad a los modelos con el menor coste total de propiedad, no sólo al coste inicial.

Paso 3: Crear un sistema de mantenimiento preventivo de tres niveles

Nivel 1: Atención básica (30% de costes)

- Buenas prácticas de lubricación: Utilice aceites API GL-5 y enjuague las líneas para eliminar partículas >50μm durante los cambios. Los sistemas de lubricación automatizados (p. ej., bombas SKF) reducen el desperdicio de grasa en 40%.

- Comprobaciones mecánicas: Reapriete los pernos según las normas ISO 6157 en cada parada para evitar fallos inducidos por vibraciones.

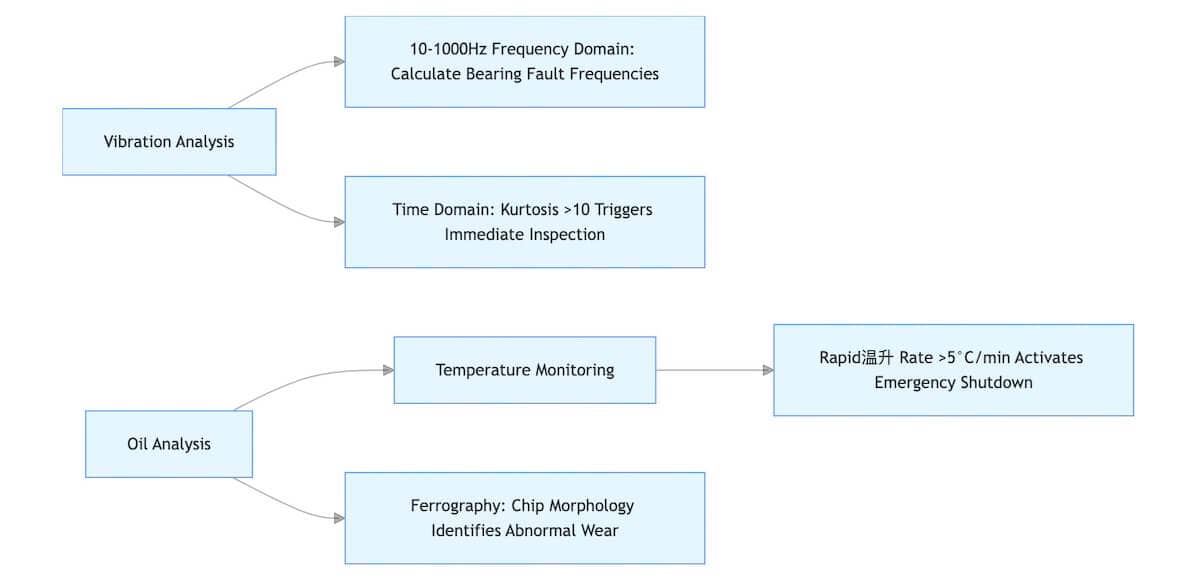

Capa 2: Condition Monitoring (60% Alertas más precisas)

Capa 3: Mantenimiento en profundidad (para revisiones)

- Protocolos de desmontaje: Documente los patrones de desgaste con fotos previas a la limpieza y mida la holgura de los rodamientos (0,02-0,04 mm tras la compensación de temperatura).

Paso 4: Aprovechar los datos para la mejora continua

Integración de herramientas digitales

- Sistemas de GMAO: Utilice plataformas como IBM Maximo para gestionar más de 200 modos de avería, generando automáticamente flujos de trabajo de reparación (por ejemplo, "¿Perforación de la superficie del diente? Sustituya el juego de engranajes").

- Modelos predictivos de IA: Entrenamiento de redes LSTM sobre datos de vibraciones para predecir fallos en el anillo exterior de los rodamientos 72 horas de antelación con una precisión de 92%.

Optimización basada en KPI

| KPI | Objetivo | Fuente de datos | Acción de mejora |

|---|---|---|---|

| Tiempos de inactividad imprevistos | <5% Anualmente | SCADA | Aumentar las inspecciones basadas en IA |

| Coste/hora de mantenimiento | <$80 | ERP | Mantenimiento dirigido por el operador (TPM) |

Paso 4: Aprovechar los datos para la mejora continua

Integración de herramientas digitales

- Sistemas de GMAO: Utilice plataformas como IBM Maximo para gestionar más de 200 modos de avería, generando automáticamente flujos de trabajo de reparación (por ejemplo, "¿Perforación de la superficie del diente? Sustituya el juego de engranajes").

- Modelos predictivos de IA: Entrenamiento de redes LSTM sobre datos de vibraciones para predecir fallos en el anillo exterior de los rodamientos 72 horas de antelación con una precisión de 92%.

Optimización basada en KPI

| KPI | Objetivo | Fuente de datos | Acción de mejora |

|---|---|---|---|

| Tiempos de inactividad imprevistos | <5% Anualmente | SCADA | Aumentar las inspecciones basadas en IA |

| Coste/hora de mantenimiento | <$80 | ERP | Mantenimiento dirigido por el operador (TPM) |

Paso 5: Mejorar la competencia de la tripulación

Matriz de competencias para las funciones

| Papel | Competencias básicas | Certificación | Examen práctico |

|---|---|---|---|

| Técnico | Análisis de vibraciones, revisión de cajas de cambios | AGMA Nivel 2 | Sustitución de piezas estándar en 4 horas |

| Ingeniero | Modelización del TCO, parametrización de la GMAO | ISO 18436-4 Nivel 3 | Revisión anual de la optimización presupuestaria |

Caja de cambios de camiones de transporte: Guía de mantenimiento especializado

Ventajas de la tecnología CRRC

- Carcasa de alta resistenciaLa aleación de aluminio 6005A-T6 reduce el peso en 20% y aumenta la resistencia a los impactos en 35%.

- Lubricación inteligente: Las válvulas sensibles a la presión ajustan el flujo de aceite en tiempo real, reduciendo el uso de lubricante en 30%.

- Vigilancia sanitaria 24/7: Los sensores de vibración-temperatura habilitados para 5G transmiten datos al instante, con una detección de fallos de <100 ms.

Ventajas de la Agencia KAIBO

- Eficiencia de costes: 15-20% precios de exportación inferiores a los de las compras directas, con condiciones flexibles (EXW/DDP).

- Adaptación personalizada: Ajusta las relaciones de transmisión y los materiales a la altitud, la temperatura y la carga útil de tu mina.

- Visitas a fábricas: Visite nuestros almacenes aduaneros de Shanghai/Qingdao y las instalaciones de fabricación de CRRC: ¡póngase en contacto con nosotros para concertar una cita!

Tareas críticas de mantenimiento

- Calibración del mecanismo de cambio: Ajuste la holgura de la horquilla de cambio a 0,1-0,3 mm con un reloj comparador; vuelva a apretar los tornillos a 45±5 N-m.

- Alineación de la transmisión: Utilizar herramientas láser para asegurar la coaxialidad caja de cambios-eje motriz ≤0,05mm-la desalineación acorta la vida de los rodamientos en 40%.

- Gestión del petróleo: Utilice aceite sintético SAE 85W-140 para -30°C-50°C; limpie los tapones de drenaje magnéticos para capturar 90% de residuos metálicos.

Envíenos un correo electrónico a info@kaiboi.com (asunto: "Haul Truck Gearbox Inquiry") para obtener especificaciones, precios o un análisis de compatibilidad gratuito.

Caso práctico: $52.000 Ahorros anuales en una mina norteamericana

- Mejora de la selección: Cambio a cajas de cambios de alta redundancia (reserva de par aumentada de 1,2x a 1,8x).

- Revisión de mantenimiento: Se ha implantado la supervisión en línea del aceite y las vibraciones, lo que ha reducido el tiempo de detección de averías de 24 a 6 horas.

- La esperanza de vida aumentó de 2 a 3,2 años (ganancia de 60%).

- Los costes anuales descendieron a $680.000, lo que supuso un ahorro de **$520.000** y una reducción del tiempo de inactividad de 150 horas.

FAQ: Mantenimiento y selección de reductores para minería

P: ¿Cuáles son los 3 factores más importantes a la hora de seleccionar reductores para minería?

- Capacidad de carga: Elija entre 1,5 y 2 veces el par nominal para la resistencia a los golpes (los reductores planetarios a medida de KAIBO soportan 25% mayores cargas para camiones de transporte).

- Entorno adecuado: Opte por clasificaciones IP67/IP68 y revestimientos resistentes a la corrosión (por ejemplo, DLC para humedad subterránea).

- Diseño de la lubricación: Dar prioridad a las cajas de cambios con refrigeración de aceite integrada (prolonga la vida útil del aceite en 30%, según datos de campo de KAIBO).

P: ¿Qué error de mantenimiento cuesta más a los mineros?

- Ignorar la contaminación por petróleo60% de averías comienzan con aceite sucio-prueba mensual de partículas metálicas (ISO 4406 ≥20/18/15 desencadena la acción).

- Mala alineación: La desalineación reduce la vida útil de los rodamientos 50%-utilice herramientas láser (el AlignmentKit de KAIBO garantiza una tolerancia de ≤0,05 mm).

- Juntas desgastadas: La entrada de polvo provoca 35% de paradas imprevistas-Las juntas de fluorocarbono de KAIBO duran 2 veces más en lugares difíciles.

P: ¿Cómo prolongar la vida útil de la caja de cambios 40%?

- Supervisión predictiva: Despliegue sensores IoT para alertas de vibración (Kurtosis >10) y temperatura (ΔT>15°C) (las cajas de engranajes inteligentes de KAIBO reducen el tiempo de inactividad en 40%).

- Mejoras materiales: Utilizar engranajes de acero carburizado (HRC 58-62) para una mayor resistencia a la fatiga 30%, según AGMA 9005-A01.

- Programación proactiva: Siga el plan de 5 pasos de KAIBO: lubrique (intervalos de 200 h), alinee, inspeccione las juntas, analice el aceite y compruebe la capacidad de carga.

Conclusión: Transformar las cajas de cambios de pasivos a activos

- 40% Mayor vida útil: Menos sustituciones significan menos inventario y mano de obra.

- $50.000+ Ahorro anual: 30% gracias a una selección inteligente, 40% gracias a un mantenimiento eficaz y 30% gracias a la reducción del tiempo de inactividad.

¿Preparado para revitalizar su proceso minero?

🌎 Visite nuestro sitio web: https://kaiboi.com

📧 Solicitar presupuesto: info@kaiboi.com