500+ Projects: Custom OEM Gearbox Solutions & 30+ Brand-Compatible Replacements for Industrial Reliability

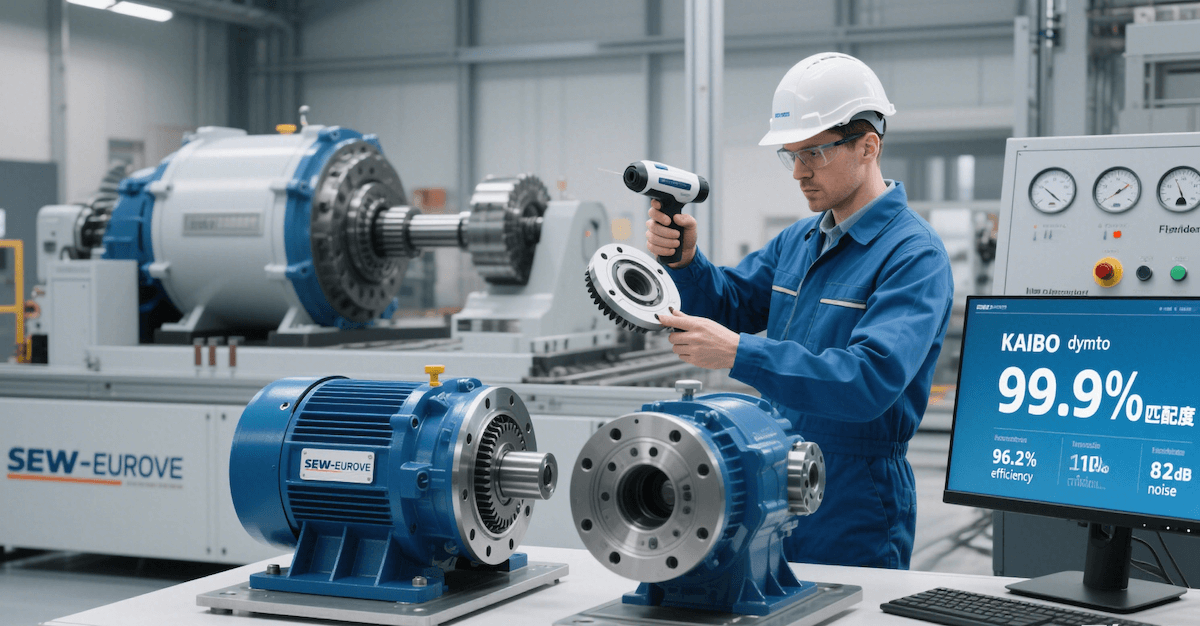

In the world of industrial machinery, reliability isn’t just a feature—it’s a necessity. For over 30 years, KAIBO has delivered 500+ custom OEM gearbox solutions and 100% compatible replacements for 30+ international brands like Flender, Winergy, and SEW-Eurodrive, achieving a 99.2% project success rate and reducing downtime by 30% on average. This article explores how our expertise in precision engineering, reverse engineering, and rigorous testing transforms equipment performance for both custom designs and brand-compatible replacements.

The Dual Power of Custom OEM & Brand-Compatible Solutions

- Custom OEM Solutions: Engineered from scratch for extreme environments (e.g., -40°C mining gearboxes).

- Brand-Compatible Replacements: 100% dimensional, material, and performance parity with OEM parts—at 30% lower cost.

Case Study 1: 50+ SEW-Eurodrive Gearbox Replacements for Spanish Rubber Plant

KAIBO’s Solution:

- 3D Reverse Engineering: Scanned original housings (±0.02mm accuracy) to replicate Flender’s proprietary design.

- Material Matching: Used identical 20CrMnTi alloy (verified via SpectroLAB) and heat treatment (HRC 35-38).

- Compatibility Testing: Passed 110% load tests and ISO 1940 vibration standards, matching SEW’s 96.2% efficiency.

Result: 25% cost savings, 3-day lead time, and zero installation issues.

Case Study 1: Custom OEM Gearboxes for Mongolian Mining

- Material Upgrades:

- Nickel-plated aluminum housings (salt spray test >1,000 hours) to resist corrosion.

- 42CrMo alloy steel gears with carburized surfaces (fatigue strength +18% vs. standard).

- Design Optimizations:

- Reinforced bearing supports to handle 8,000N・m 冲击 loads.

- Labyrinth seals to prevent dust ingress (particle filtration ≥50μm).

- Testing Rigor:

- 1,000-hour thermal cycling test (-40°C to +80°C).

- Dynamic balancing to ≤2g·mm residual unbalance (ISO 1940 G1.0 grade).

The KAIBO Quality Framework: 7 Stages for Custom & Replacement Gearboxes

Our ISO 9001:2015-certified process integrates brand-compatibility workflows into every stage:

1. Requirement Analysis (Now with Reverse Engineering)

- Custom OEM: 30-point questionnaire for unique specs (e.g., FDA-compliant lubricants for food processing).

- Brand Replacements: 3D scanning of legacy parts (10,000+ data points) and OEM manual cross-referencing (e.g., AGMA 2009-B01 for gear teeth).

2. Material Selection (Unified Quality Standards)

- Both custom and replacement gearboxes use Tier 1 alloys:

- 42CrMo for high-torque applications (mining, wind energy).

- Nickel-plated aluminum for corrosion resistance (rubber extrusion, coastal equipment).

3. Precision Machining (Brand-Specific Tooling)

- Custom OEM: KAPP NILES grinders for Ra ≤0.4μm surface finish.

- Brand Replacements: OEM-specified tools (e.g., Carbide end mills for SEW-Eurodrive’s helical gears) to replicate proprietary profiles.

4. Assembly in Cleanroom Environments

In ISO 8 cleanrooms (class 100,000):

- Torque wrenches (±2% accuracy) tighten fasteners to OEM specs.

- Ultrasonic cleaning (40kHz, 15 minutes) removes all particulates >50μm.

5. Full-Load Performance Testing (Dual Compliance)

- Custom OEM: Simulates 120% load (AGMA 9005).

- Brand Replacements: Verifies 100% OEM performance parity (e.g., Flender’s 82dB noise limit, Winergy’s 97% efficiency).

6. IoT Monitoring & 7. Continuous Improvement

Optional sensors track 50+ parameters in real time, including:

- Gear mesh temperature (alert threshold +10°C above baseline).

- Bearing vibration acceleration (predicts failure 30 days in advance).

7. Continuous Improvement

Our R&D team reverse-engineers field data to drive annual upgrades, such as:

- 2024: Upgraded heat treatment reduced gear wear by 22% in high-dust environments.

- 2025: New lubricant formulation extended oil change intervals by 50% for food processing gearboxes.

Why Custom OEM Outperforms Standard Solutions

| Metric | Custom OEM Gearbox | Standard Gearbox |

|---|---|---|

| Mean Time Between Failures (MTBF) | 85,000 hours | 50,000 hours |

| Energy Efficiency | ≥96% | 88-92% |

| Maintenance Interventions/Year | 2-3 times | 5-6 times |

Industry Applications: Beyond One-Size-Fits-All

1. Rubber & Plastics Machinery

- Solution: Acid-resistant coatings for PVC extrusion (pH 2-13 tolerance).

- Result: 40% longer lifespan in corrosive plasticizer environments.

2. Food & Beverage Processing

- Solution: FDA-compliant lubricants and smooth-surface finishes (Ra ≤0.8μm).

- Compliance: Meets 21 CFR Part 178.3570 for direct food contact.

3. Renewable Energy

- Solution: High-efficiency helical-bevel gears for wind turbines (gear ratio 50:1, efficiency 97%).

- Impact: Reduced energy loss by 3% across a 50-turbine farm—equivalent to powering 1,200 homes annually.

Ready to Transform Your Equipment Reliability?

- Faster Time-to-Market: 8-week lead times for most custom designs.

- Global Compliance: CE, UL, ATEX, and FDA certifications available.

- Data-Backed Guarantees: 3-year warranty—twice the industry average.

Ready to Revitalize Your Machinery?

🌎 Visit our website: https://kaiboi.com

📧 Request a quote: info@kaiboi.com