OEM/ODM Support|High-Precision | ISO 9001-certified|

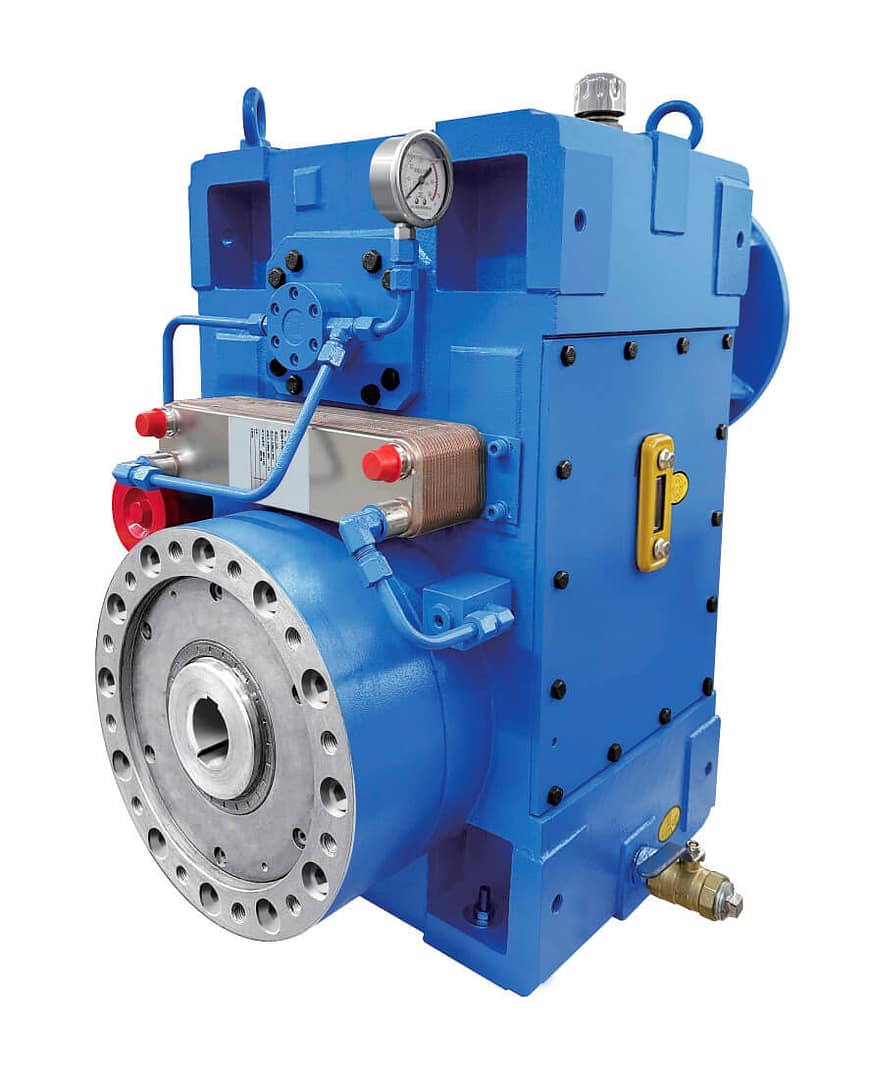

Custom Industrial Gearbox

Why Choose Our Custom Industrial Gearbox?

KAIBO, 30+ year ISO 9001-certified custom industrial gearbox manufacturer in China, operates a 27,000㎡ factory with KAPP NILES grinding and Gleason hobbing machines. We deliver high-precision, reliable gearboxes for heavy-duty industries like oil & gas, marine, mining, and wind turbine. Trust KAIBO for custom industrial gearbox solutions blending decades of expertise with cutting-edge technology.

OEM/ODM Support|High-Precision | ISO 9001-certified|

Custom Industrial Gearbox For Multiple Industries

Specialize in custom mining gearbox designs as part of our custom industrial gearbox solutions. Our heavy-duty mining gearboxes (2–1,400 kNm torque) feature 42CrMo4 quenched steel gears (HRC60–62) and GGG70 housings, offering 30% improved abrasion resistance for extreme mining conditions. KAPP NILES grinding ensures ISO 3 precision and 97.8% energy efficiency, optimizing performance for mining trucks, conveyors, crushers, and mining winch gearbox systems. Planetary gearbox mining designs with 25° pressure angles boost load capacity by 25%, while PTFE coatings reduce dust adhesion by 50%. ISO 9001-certified and built for dust, vibration, and extreme temps, our gearboxes deliver MTBF 2,500+ hours and cut downtime by 40%. Ideal for hoists, excavators, bulk material handling, and winch applications. Trust our rugged, high-torque solutions for reliable mining operations.

Engineer rugged custom marine gearboxes for extreme marine environments. Our high torque marine gearboxes (50–2,000 kNm) feature SS316L stainless steel gears with nickel-phosphorus coatings, delivering 50% corrosion resistance and passing 1,500-hour salt spray tests. Gleason hobbing ensures ISO 4 precision and 98.2% energy-efficient transmission, reducing noise to ≤10dB for ship propulsion, deck cranes, and marine winch gearbox systems. Tailored planetary designs with double-row bearings boost axial load capacity by 30%. DNV-GL-certified, our gearboxes withstand -30°C to +70°C conditions with MTBF 3,000+ hours, ideal for offshore vessels, tugboats, and dredging equipment. Features include leak-proof seals and low-vibration performance. Contact for durable, high-precision solutions for marine pumps, anchor winches, and heavy-duty applications.

Engineer rugged custom Oil Drilling Gearbox solutions for extreme oilfield environments. Our high-pressure gearboxes (500–5,000 kNm torque) feature 4140 alloy steel gears (HRC58) and dual-lip seals, delivering leak-proof performance for offshore drilling gearbox systems, drilling rigs, pumps, and fracking equipment. CNC hobbing ensures ISO 5 precision and 97.5% high-speed transmission efficiency (up to 15,000 RPM), withstanding 200°C temperatures and harsh vibrations. Worm gear designs with thermal balancing reduce oil degradation by 25%, while API 617-compliant housings enable 10,000+ hours of continuous operation—ideal for drilling rig gearbox maintenance efficiency. Engineered for robotic drilling gearbox integration, our solutions offer precise motion control and durability in automated systems. Trust our high-speed gearbox for oil drilling to enhance productivity in offshore platforms, refineries, and heavy machinery.

Engineer high-efficiency wind turbine gearboxes (3MW–12MW) with planetary gearbox for wind turbine designs, including tailored solutions for floating wind turbine gearbox systems. Our custom wind turbine gearbox features carburized steel gears (HRC62) and ISO 3 precision (≤0.0015mm error) via KAPP NILES grinding, achieving 98.7% transmission efficiency and 10dB noise reduction—critical for floating turbines’ dynamic load environments. Planetary stages with 38° helix angles optimize load distribution for offshore wind turbine gearbox systems, reducing vibration by 50% to withstand salt spray and wave-induced motion. IEC 61400-certified and IP66-sealed, our gearboxes endure 20+ years of operation with MTBF 4,000+ hours and minimal wind turbine gearbox maintenance. Ideal for floating turbines, gearless drivetrains, and high-wind regions, they deliver 47% YoY export growth. Contact for lightweight, durable solutions compliant with offshore and floating wind standards.

High-Torque|IP68 Protection|Planetary Drive

Custom Industrial Gearbox Technical Specifications

| Parameter | Typical Value | Customizable Range | Notes |

|---|---|---|---|

| Torque Range | 100N·m ~ 5,000N·m | ≤20,000N·m (Super-heavy duty) | Carburized and quenched for tooth surface hardness |

| Input Power | 0.1kW ~ 500kW | 0.01kW ~ 5,000kW (Heavy-duty) | Suitable for wind turbines, mining crushers |

| Transmission Ratio | 1:1 ~ 30:1 (Helical Gear) | 1:1 ~ 100:1 (Planetary Gearbox) | Planetary gears for high-torque, low-speed applications |

| Output Speed | 10rpm ~ 3,000rpm | 5rpm ~ 5,000rpm (High-speed precision) | High-speed for food production, low-speed for mining |

| Mounting Method | Flange Mount (SAE Standard) | Base Mount/Shaft Mount/Embedded/Torque Arm | 3D mounting drawings and on-site commissioning |

| Material | 20CrMnTi Carburized Alloy Steel (HRC58-62) | 42CrMo High-strength Steel/17-4PH Stainless Steel/Ceramic Composite | Stainless steel compliant with FDA food standards |

| Ambient Temperature | -20℃ ~ 80℃ | -40℃ ~ 120℃ (High/low-temperature coatings) | Lithium-based grease for low temps, synthetic oil for high temps |

| Protection Class | IP65 (Dust/Water Protection) | IP67/IP68/IP69K (Explosion-Proof/High-Pressure Water) | ATEX-certified for explosive atmospheres (chemical industry) |

| Noise Level | ≤75dB (1m distance, helical gear) | ≤65dB (Low-noise optimized design) | Tooth profile modification and damping coating to reduce vibration |

| Efficiency | ≥95% (Helical gear) | ≥97% (Planetary gearbox) | Compliant with EU ErP Directive for carbon reduction |

Let's Start Your Machinery To Be Realized

Custom Industrial Gearbox Solutions for Precision Manufacturing – Powered by ISO 9001-certified engineering and cutting-edge gear machining technology, delivering reliable, high-efficiency performance for your machinery.

End-to-End Customization for Heavy-Duty Industries

Our 6-Step Customization Process

Deep-dive into client specs: torque , speed, environment (offshore/mining/wind). Map to equipment (pumps/conveyors/extruder). Align with “custom gearbox requirements assessment” “industrial application needs” to design failure-proof solutions.

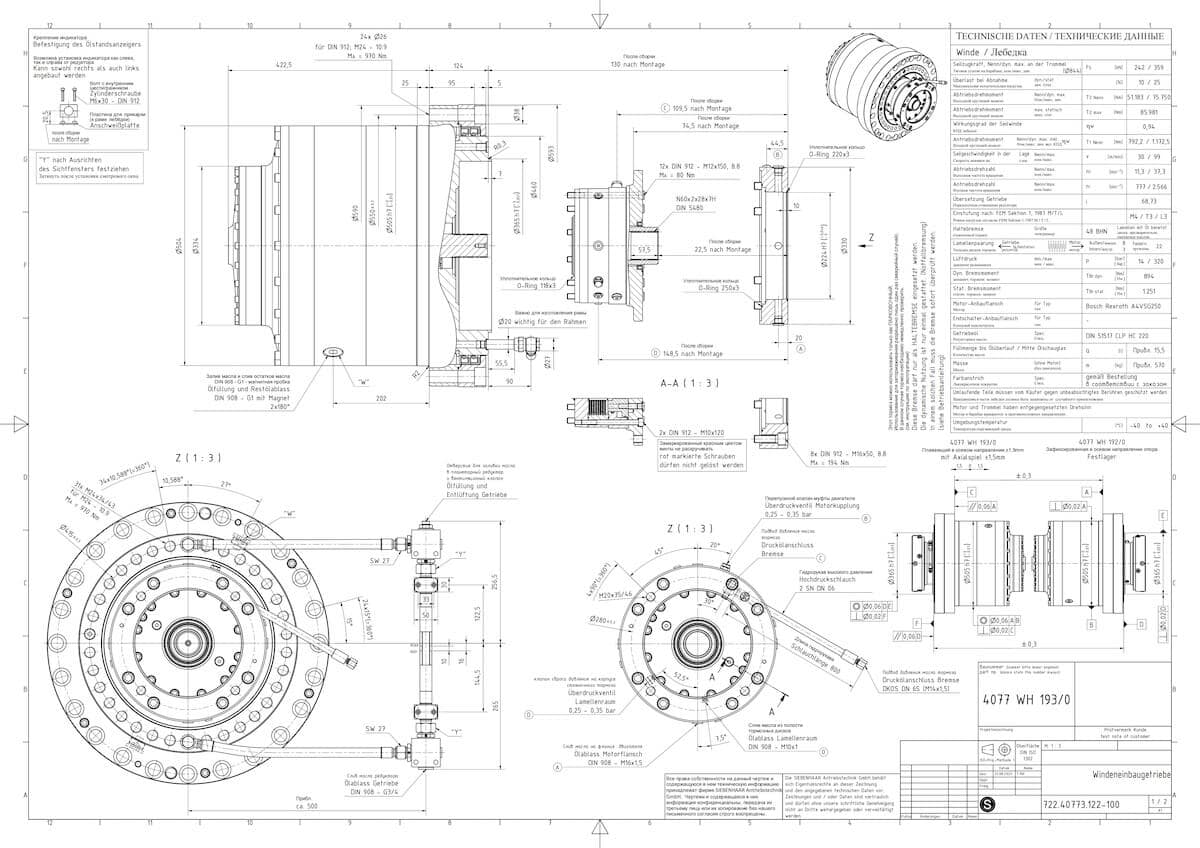

Engineer bespoke gearbox blueprints (planetary/helical) via CAD/FEA. Integrate API 617 (oil&gas), IEC 61400 (wind) compliance. Use “engineered planetary gearbox solutions” “application-specific gear ratio design” for max efficiency (≥98.5%).

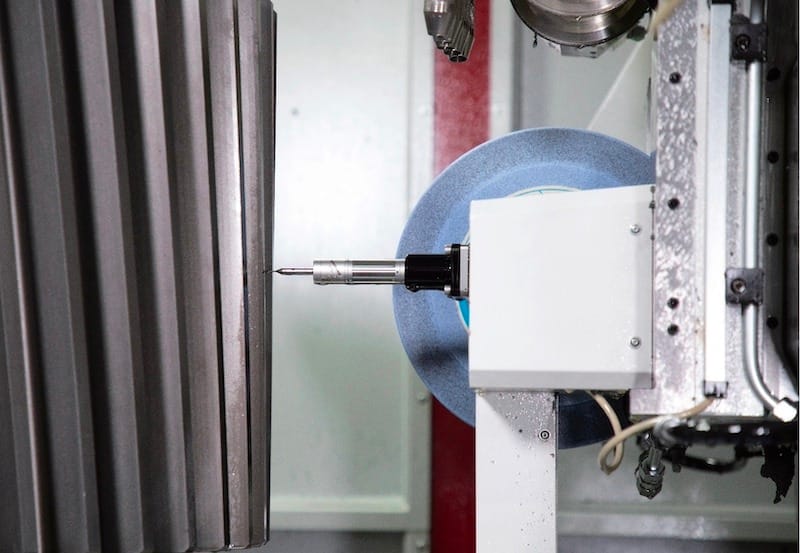

Produce gearboxes via Gleason hobbing and Kapp Niles grinding alloy steel 4140 HRC58–62. Ensure ISO 3 precision ≤0.001mm error. Focus on "CNC machined gearbox components" "high-torque gearbox production" for zero-defect 30+ year durability.

Validate efficiency (ISO 1940) noise (<8dB) vibration (≤1.5mm/s²) using German WENZEL three-coordinate measuring machines for gear geometry precision. Conduct 1500-hour load tests and thermal cycling. Leverage industrial gearbox load testing gearbox durability validation to guarantee MTBF >3000 hours.

Expedite global shipment via bonded warehouses + express lines. Prioritize “on-time custom gearbox delivery” “expedited industrial gearbox shipping” to cut project downtime by 40%. Trackable from factory to site.

Provide preventive maintenance, emergency repairs, OEM spare parts. Offer “gearbox maintenance contracts” “mining gearbox repair services” with 24/7 support. Extend lifecycle for offshore/wind/heavy machinery sectors.

Proven Custom Solutions Across Industries

Custom Offshore Crane Gearbox for Oil & Gas | Middle East - 50°C Heat & Salt Spray Resistant

Custom Mining Gearbox | 10,000 kNm Torque, Russian Arctic-Resistant for Extreme Operations

Custom Industrial Gearbox for Vietnam Plastic Extruder | High-Torque, Tropical-Ready Design

What Are You Waiting For...

GET A FREE QUOTE TODAY