Chinaplas 2025: Empowering Global rubber and plastics machine with Dedicated Reducers

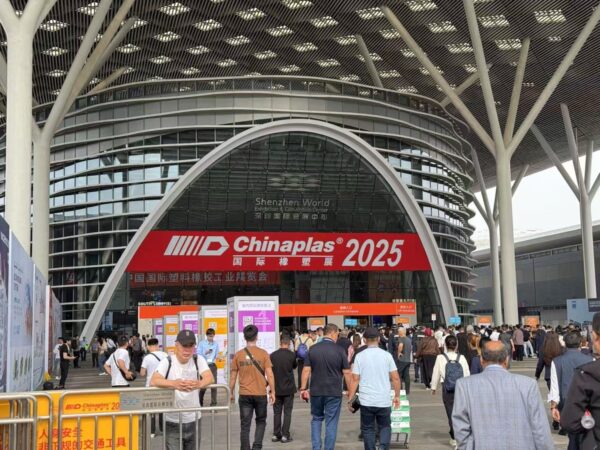

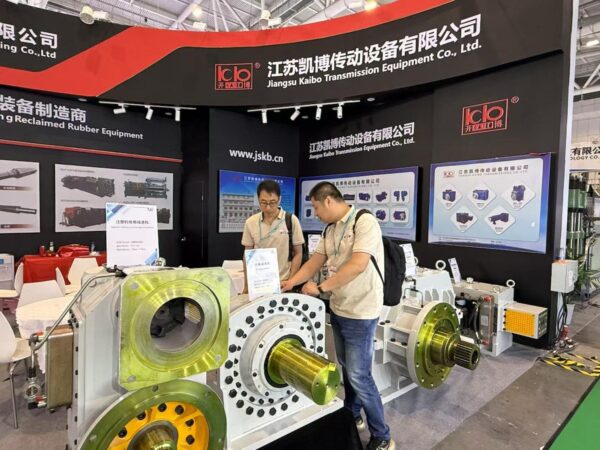

From April 15-18, 2025, our factory took center stage at CHINAPLAS 2025 in Shenzhen, presenting dedicated reducers for rubber and plastic machinery to a global audience of manufacturers, engineers, and industry leaders. Our booth highlighted how these solutions address the unique challenges of extrusion, injection molding, blow molding, and recycling lines, attracting over 300 qualified leads from 40+ countries, including major players like SABIC, Wanhua Chemical, and Arburg.

Key Innovations in Dedicated Reducers for Rubber And Plastic Machinery

1.Tailored Solutions for Diverse Processes

- Rubber Extrusion & Plastic Extrusion:

Our ZLYJ series dedicated reducers (e.g., ZLYJ200, ZLYJ330) for extruders featured high-torque helical gear systems (up to 50,000 N·m) and temperature-resistant coatings (withstanding 220℃), optimizing melt quality in PVC pipe, TPE compound, and tire tread production. - Injection Molding & Blow Molding:

The ZWBPD028028 planetary reducers offered ultra-low backlash (≤1 arcminute) and IP67 sealing, ensuring precision in medical device molding and large-scale automotive part production (e.g., bumpers, dashboards). - Recycling & Compounding:

Newly launched REX series reducers integrated wear-resistant carbide gears, reducing downtime in PET bottle recycling and post-consumer resin compounding—critical for circular economy initiatives.

2.Engineered for Efficiency & Durability

- Energy Savings:

Our dedicated reducers for rubber and plastic machinery achieved 25-30% energy efficiency gains via optimized gear ratios and low-friction bearings, aligning with Chinaplas 2025’s focus on sustainable manufacturing. - Rugged Design:

Using 20CrMnTi carburized steel and anti-corrosive surface treatments, these reducers withstand harsh environments in offshore rubber processing and high-humidity plastic extrusion plants.

3.Customization for Every Application

- Parameter Flexibility:

We showcased 1,000+ models with adjustable torque (50-50,000 N·m), speed ratio (5:1-100:1), and mounting configurations, catering to both small-scale lab extruders and mega-ton industrial molding machines. - Global Compliance:

All reducers meet ISO 9001, CE, and UL standards, with specialized versions for FDA-approved medical equipment and ATEX-certified explosive environments.

Why Our Gear Reducers Stand Out

- Material Excellence: We use high-strength alloy steel and corrosion-resistant coatings , ensuring durability in harsh environments.

- Customization: From micro-gearboxes (Φ28mm ) to heavy-duty reducers (≤1,000kg ), we offer tailored solutions for extrusion, injection, and blow molding applications.

- Compliance: All products meet ISO 9001, CE, and RoHS standards, with UL certification available for North American markets.

Connect with Us Post-Show

Relive our Chinaplas 2025 highlights and explore how dedicated reducers for rubber and plastic machinery can elevate your operations:

🌎 Visit our website: https://kaiboi.com

📧 Request a quote: info@kaiboi.com