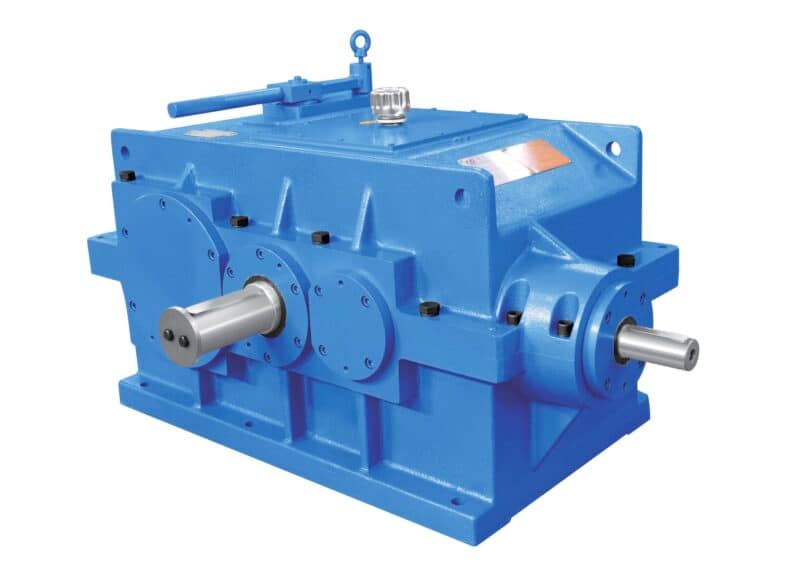

علبة تروس التعدين

صُممت علبة تروس KAIBO الخاصة بالتعدين للخدمة الشاقة لمعدات التعدين القوية. وبفضل السبائك المقاومة للتآكل، والمبيت المقاوم للصدمات، والتشحيم الذكي، فإنها توفر نقلًا موثوقًا عالي العزم في بيئات التعدين القاسية. مثالية للكسارات، وأنظمة النقل، وماكينات الطحن. وبصفتنا شركة تصنيع علب التروس الصناعية المخصصة، فإننا نقدم تخصيصًا سريعًا ودعمًا لما بعد البيع على مدار الساعة طوال أيام الأسبوع.

نظرة عامة على المنتج

تم تصميم علبة تروس التعدين للخدمة الشاقة من KAIBO، الحاصلة على شهادة ISO 9001، خصيصًا لتطبيقات التعدين الشاقة (الكسارات، وأنظمة النقل، ومعدات الطحن). وباعتبارنا شركة موثوق بها في تصنيع علب التروس الصناعية المخصصة، فإننا نتعامل مع تحديات الأحمال القصوى من خلال طحن التروس الدقيق 20CrMnTi ومبيت فولاذي مزور، مما يتيح التشغيل الفعال 97% الذي يقلل من تكاليف الطاقة بمقدار 18% لعمليات التعدين المستمرة ويتحمل درجات الحرارة المحيطة 500 درجة مئوية. تم تحسين علبة التروس لتناسب البيئات عالية التأثير والغبار، مما يضمن أداءً مستقرًا في التعدين تحت الأرض والتعدين في الحفر المفتوحة.

المزايا الأساسية

- هيكل من الفولاذ المطروق المتين: يقاوم الصدمات والتآكل والغبار في ظروف التعدين القاسية.

- تروس السبائك المعالجة حرارياً: أرضية دقيقة لنقل عزم الدوران بسلاسة تحت الأحمال الثقيلة.

- نظام التشحيم القسري الذكي: تراقب جودة الزيت ودرجة حرارته، مما يقلل من الصيانة بمقدار 30%.

- تصميم التعدين للخدمة الشاقة: يدعم تطبيقات عزم الدوران العالي للأسطوانات والأعمدة ذات الأقطار الكبيرة.

- ضوضاء واهتزازات منخفضة:: ≤80 ديسيبل (محملة) عن طريق تحسين التوازن الديناميكي.

- اختبار صارم لقوة التحمل: 10,000 ساعة من الدورات تضمن عمر خدمة طويل في البيئات القاسية.

- ارتفاع - أداء عزم الدوران العالي: مصممة لإخراج عزم دوران استثنائي، والتعامل مع الأسطوانات/الأعمدة ذات القطر الكبير. تعمل على تشغيل الكسارات/الناقلات بتشغيل مستقر وفعال، مما يقلل من مخاطر التوقف في المهام الشاقة.

- نقل عالي الكفاءة: يحقق كفاءة تشغيلية 97%، مما يقلل من تكاليف الطاقة بمقدار 18% للتعدين المستمر. تصميم تروس متقدم يقلل من فقدان الطاقة لعمليات مستدامة.

- التخصيص المخصص للتعدين حسب الطلب: كشركة مصنعة لعلبة تروس صناعية مخصصة، نقدم حلولاً مصممة خصيصًا لطاقة الإدخال، ونسبة التروس، وعزم الدوران، والتركيب - مثالية لإعدادات التعدين الفريدة.

سيناريوهات التطبيق

- أنظمة التكسير الأولية/الثانوية لمعالجة الخامات

- السيور الناقلة في نقل المعادن لمسافات طويلة

- ماكينات التفريز بالكرات/القضبان لطحن الخام.

- محركات شاحنة السحب للنقل الثقيل

- لوادر التعدين تحت الأرض تتطلب عزم دوران عالي في الأماكن الضيقة.

المواصفات الفنية

| المعلمة | القيمة النموذجية | الملاحظات |

|---|---|---|

| طاقة الإدخال | 15-500 كيلوواط (قابلة للتخصيص) | تناسب الكسارات والطواحين والمحركات الناقلة. |

| سرعة الإدخال | ≤1500 دورة في الدقيقة | تتوافق مع محركات التعدين القياسية؛ متوافقة مع محركات التردد المتغير. |

| نسبة التروس | 8-80 (قابل للتخصيص) | عزم دوران عالٍ للتكسير منخفض السرعة أو النقل عالي السرعة. |

| عزم الدوران الناتج | 15,000-120,000 نيوتن-متر (قابل للتخصيص) | محرك مستقر للأسطوانات ذات القطر الكبير في الأحمال الثقيلة. |

| سرعة الإخراج | 20-1000 دورة في الدقيقة (حسب النسبة) | يتكيف مع سرعات الحزام الناقل من 5-50 م/ثانية. |

| طريقة التركيب | شفة/عمود الدوران (قابل للتخصيص) | تركيب سريع لإعدادات التعدين القياسية أو غير القياسية. |

| درجة الحماية | IP66 (IP68 اختياري) | حماية ضد الغبار/دخول الماء؛ IP68 للتطبيقات الغاطسة. |

| مستوى الضوضاء | ≤80 ديسيبل (محمّل، مسافة 1 متر) | يفي بمعايير الضوضاء الصناعية لمواقع التعدين. |

| الكفاءة | ≥96% (يعتمد على النسبة) | تقلل الكفاءة العالية من استهلاك الطاقة في العمليات على مدار الساعة طوال أيام الأسبوع. |

3 خطوات للاختيار السريع

- تحديد نوع المعدات: تحديد ما إذا كانت للتكسير أو النقل أو الطحن - لكل منها متطلبات تحميل فريدة من نوعها.

- مشاركة المعلمات الأساسية: قدم سرعة الإدخال ونسبة التروس المطلوبة وعزم دوران الخرج. سيوصي مهندسونا بنماذج في غضون 24 ساعة.

- طلب حلول مخصصة: بالنسبة للاحتياجات الخاصة (مقاومة للانفجار، ودرجات الحرارة العالية، والواجهات غير القياسية)، تصميمات مصممة خصيصًا مع مهلة زمنية تتراوح بين 4 و8 أسابيع.

هل أنت مستعد لتنشيط عملية التعدين الخاصة بك? دعنا نتحدث

🌎 زيارة موقعنا الإلكتروني https://kaiboi.com

📧 طلب عرض أسعار: info@kaiboi.com

الأسئلة الشائعة

س: كيف أختار علبة التروس المناسبة لمعدات التعدين الخاصة بي؟

A: ابدأ بتحديد نوع معداتك (على سبيل المثال، طراز الكسارة) ومعلمات التشغيل (السرعة/عزم الدوران). سيقوم فريقنا بإجراء تحليل التوافق واقتراح الخيارات - لا حاجة إلى حسابات معقدة، فقط استشارة فنية مباشرة.

س: ما هي المهلة الزمنية اللازمة لصناديق تروس التعدين المخصصة؟

A: يتم شحن النماذج القياسية في غضون 72 ساعة. تستغرق التصاميم المخصصة من 4 إلى 8 أسابيع، مع توفير تتبع الطلب في الوقت الفعلي.

س: كيف تتم صيانة علبة تروس التعدين في البيئات القاسية؟

A: الصيانة المنتظمة هي المفتاح. استبدل زيت التروس كل 1000 ساعة لصناديق التروس الجديدة، ثم كل 6 أشهر أو 5000 ساعة باستخدام زيوت اصطناعية عالية اللزوجة (مثل ISO VG 460 EP). افحص التروس كل ثلاثة أشهر بحثًا عن التآكل والمحامل بحثًا عن أي تآكل أو ضوضاء. راقب درجة حرارة الزيت (أقل من 80 درجة مئوية) واستخدم تحليل الاهتزاز للتنبؤ بالمشكلات. بالنسبة للبيئات المتربة، قم بالترقية إلى حماية IP68 والأغلفة محكمة الغلق.