عملية اختيار سريعة من 3 خطوات

- تحديد نوع المعدات: حدد ما إذا كان للتحبيب أو الغشاء المصبوب أو بثق الصفيحة لمطابقة متطلبات الحمولة.

- مشاركة المعلمات الأساسية: قدم سرعة الإدخال ونسبة التروس المطلوبة وعزم دوران الخرج. سيوصي مهندسونا بنماذج في غضون 24 ساعة.

- طلب حلول مخصصة: بالنسبة للاحتياجات الفريدة (مقاومة درجات الحرارة العالية، أو التصميمات المقاومة للانفجار، أو الواجهات غير القياسية)، نقدم حلولاً مصممة خصيصًا مع مهلة تتراوح بين 4 و6 أسابيع.

هل أنت جاهز لتنشيط عملية الطارد الخاص بك? دعنا نتحدث

🌎 زيارة موقعنا الإلكتروني https://kaiboi.com

📧 طلب عرض أسعار: info@kaiboi.com

📂 تنزيل مجاني : دليل اختيار علبة تروس الطارد.PDF

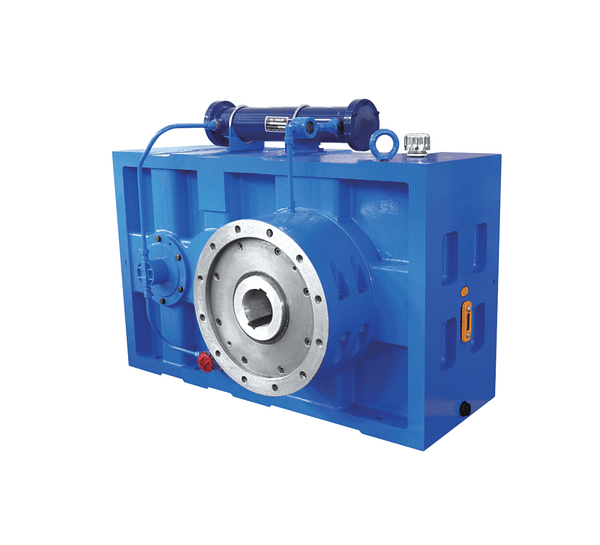

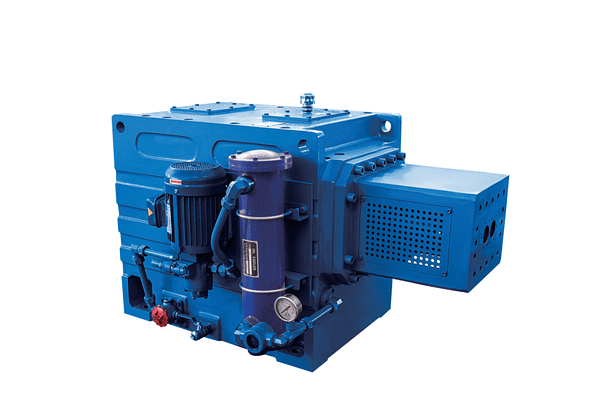

علبة تروس الطارد

تتصدى علبة تروس الطارد من KAIBO، وهي حل حاصل على شهادة الأيزو 9001 ومصممة خصيصًا لأجهزة بثق البلاستيك (أنظمة التحبيب وخطوط التغليف المصبوب وماكينات بثق الصفائح)، لتحديات نقل الطاقة ذات الأحمال العالية بموثوقية لا مثيل لها. تضمن علبة التروس هذه، المصنوعة من طحن التروس الدقيق 18CrNiMo7-6 ومبيت من حديد الدكتايل كفاءة تشغيلية تبلغ 98%، مما يقلل من تكاليف الطاقة بمقدار 15% في تحبيب PP/PE ويتيح إنتاج أفلام عالية السرعة بسرعة 200 متر/دقيقة. إن مستوى الضوضاء الذي يبلغ ≤75 ديسيبل (بدون تحميل) وتصميمه القوي، مدعومًا بخبرة KAIBO كشركة رائدة في تصنيع علب التروس الطاردة، يجعله مثاليًا للتطبيقات الصناعية المستمرة حيث المتانة والدقة غير قابلة للتفاوض.

المزايا الأساسية

- سبائك عالية القوة ومبيت من حديد الاطالة وحديد الدكتايل: مصممة لمقاومة التشوه والتآكل، مما يضمن ثباتاً طويل الأمد حتى في ظل الأحمال الثقيلة.

- التروس المصنوعة من سبيكة دقيقة التحضير: توفر هذه التروس المعالجة بالحرارة للحصول على صلابة مثالية، نقل سلس للطاقة بأقل قدر من التآكل.

- هندسة الطارد المخصص: مصممة خصيصًا للتعامل مع الأحمال المحورية/الشعاعية العالية، وتثبيت البراغي الكبيرة للحصول على جودة بثق متسقة.

- تشغيل منخفض الضوضاء للغاية:: ≤75 ديسيبل (بدون تحميل عند متر واحد) تم تحقيقه من خلال تحسين ملامح أسنان التروس وديناميكيات المبيت.

- اختبار الجودة الصارم: تخضع كل علبة تروس لاختبار الحمل الديناميكي، وتحليل الاهتزاز، والدورة الحرارية لضمان الحد الأدنى من الصيانة وعمر خدمة يزيد عن 10000 ساعة.

سيناريوهات التطبيق

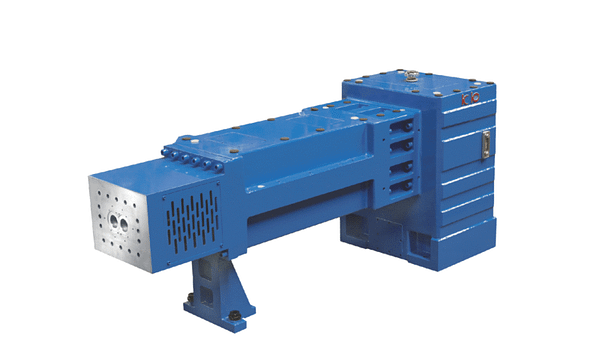

- تحبيب PP/PE: محركات لولبية عالية السرعة للتكوير الفعال في إعادة التدوير والتصنيع.

- خطوط الأفلام المصبوبة عالية السرعة: التحكم الدقيق في السُمك للأغشية المستخدمة في التعبئة والتغليف والزراعة والقطاعات الطبية.

- بثق الألواح ذات الأحمال الثقيلة: إنتاج صفائح ABS/PVC لتطبيقات البناء والسيارات والتطبيقات الصناعية.

- أنظمة الإنتاج الموفرة للطاقة: مثالية للعمليات التي تعمل على مدار الساعة طوال أيام الأسبوع، مما يقلل من البصمة الكربونية والتكاليف التشغيلية.